The Crux of the Construction Challenge? Productivity, Sustainability, and Change

Posted on 11 April 2025

When asked about the challenges and opportunities that Victaulic faces, the topics that recur are productivity, sustainability, and change. These themes are prevalent across the whole construction industry and 2025 marks a pivotal moment for transformation. There are quicker, better, and more efficient ways of doing things that can be adopted now to maintain construction growth. The question is, how can we shift the needle when the status quo is so ingrained in the industry?

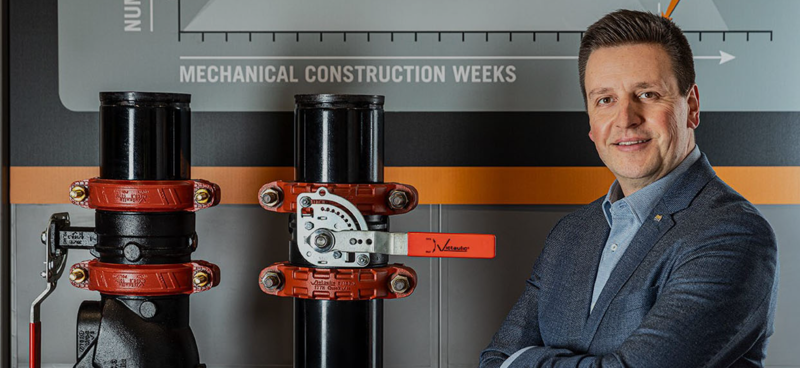

Here, Branden Kotyk, general manager at Victaulic, delves into how each of these points are being addressed across Europe.

The construction industry is largely founded on traditional methods

The construction industry, regardless of location, is made up of predominantly small to medium-sized companies. In fact, according to the European Commission, up to 95% of construction, architecture, and engineering firms are micro-enterprises, many with fewer than 25 employees. These companies often have substantial personal investment, a long-standing history and reputation, and are therefore particularly averse to change, which can feel like a risk compared to the way they have always done things.

Flame-based pipe joining methods take time. With welding, for example, not only are there intense heat, sparks, and fumes, but a specialist welder is also required. The process is slow and multiple measures and tests are needed to ensure safety and joint integrity. Once the piping is installed, it’s virtually impossible to reconfigure the system without cutting pipe and generating waste. As the trends for the rapid construction of data centers, commercial buildings, warehouses, and battery plants, as well as the reclassification of empty office buildings continue through 2025, flexible, reconfigurable solutions will be more crucial than ever.

When it comes to pipe-joining, Victaulic specializes in providing grooved mechanical pipe-joining solutions that are a better alternative to welding, flanging and other joining methods. Victaulic provides a solution that is up to ten times faster to install, is easy to use and is ultra-reliable.

Switching from welding to grooved mechanical pipe-joining for the first time can feel like a leap of faith, especially since it’s challenging to compare costs directly. The significant savings on labor, both crew size and time spent on site, and the reduction of potential unexpected

Expenses make the overall installed cost substantially lower. Grooved mechanical systems also make accommodating any differences between the plans and real-world situation much easier and help to prevent any alignment issues often faced with flanged systems. There is also a simple, visual inspection of whether the couplings have been installed correctly and they can be easily adjusted if required, again avoiding costly rework.

Once contractors experience these benefits for themselves, we find they start to use Victaulic across their projects but effecting change within an industry dominated by small but impressive businesses takes time. It’s a gradual process that has to be underpinned by trust, familiarity, and in the longer term, acceptance of new technologies and methods.